Award-winning industrial design and product development

Lead by Design

We work with disruptive teams from all over the world. From Sweden to China. Together we research, design, prototype and test new, novel solutions. In Hong Kong we benefit form being close to suppliers in Shenzhen. Here our Industrial Design and Mechanical Engineering teams can faster integrate with our clients supply chain. The access greatly increase speed and feasibility of deliveries.

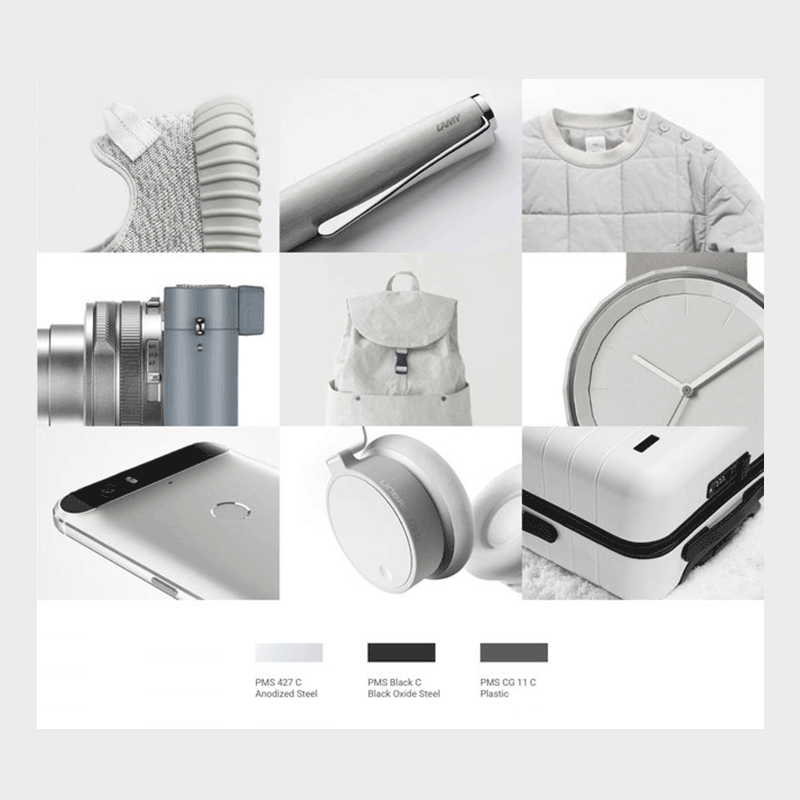

A powerful method to understand the ‘soft’ values of design is to visualise the stylistic elements of a product. It is also good for team building and encouraging creativity and aligning artistic directions. The boards can visualise many different scenarios like:

- Lifestyle

- Mood

- Styling

- Usage and context

When a concept is still in its early stage, 3D product rendering and animation can be used to create a broader understanding of the idea together with compelling imagery to sell the story to clients and stakeholders.

Later in the project when the design is completed we produce photo realistic 4K renders and animations for websites, hero imagery for packaging and all types of content marketing.

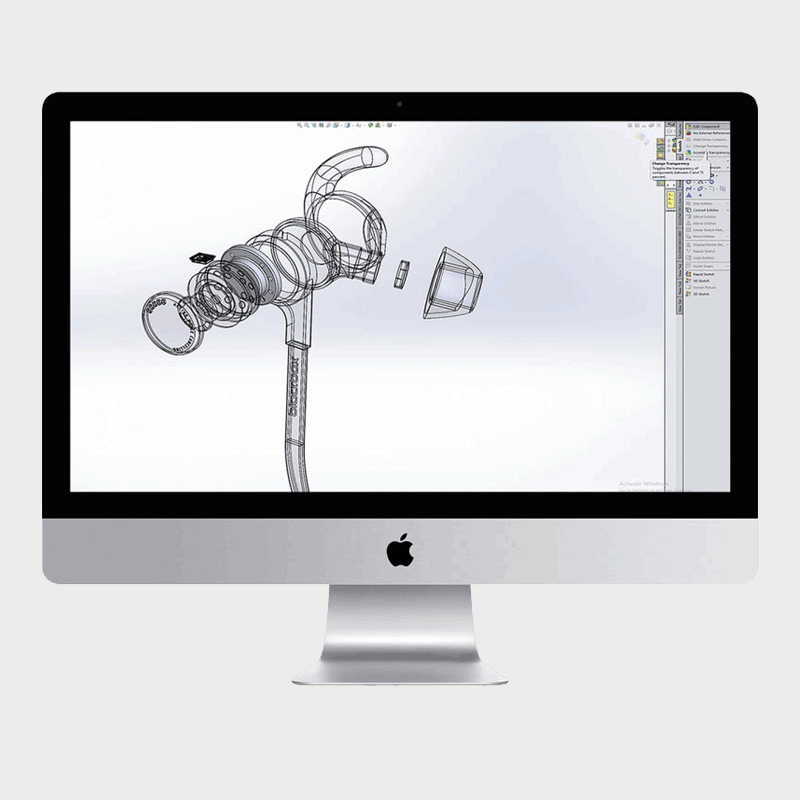

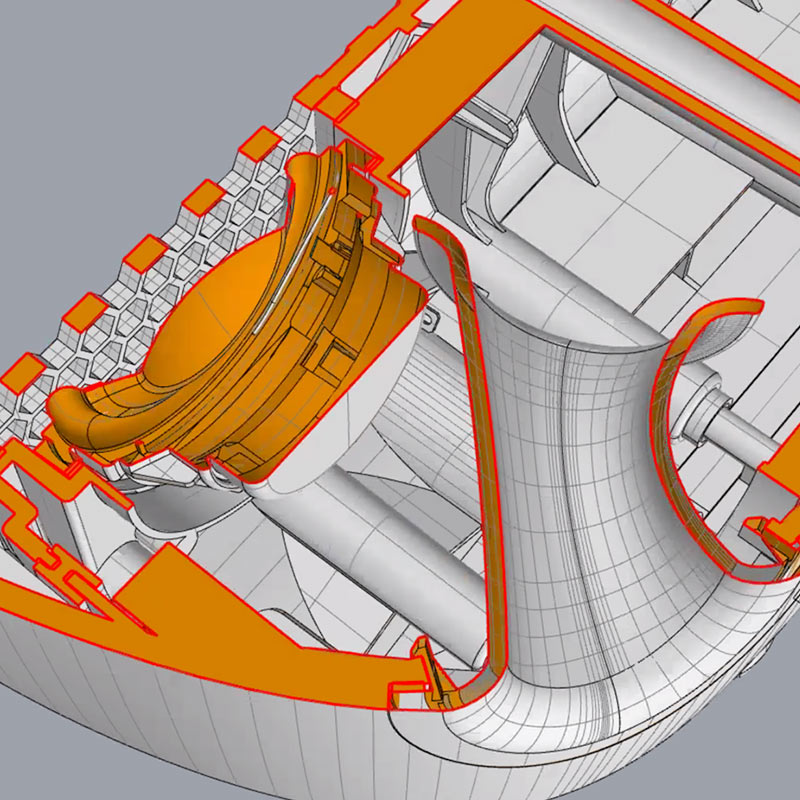

CAD software is an indispensable tool for designers. CAD software also allows designers to experiment with different materials. It aslo enables designers to communicate their designs more effectively with stakeholders and clients.

By presenting 3D models we can better convey the idea and demonstrate how the design will look and function in the real world.

CMF

The selection of color, materials, and finish (CMF) in product design is critical as it can greatly impact how the product is perceived by users. The right combination of CMF can make a product feel high-end and durable, while the wrong combination can make it feel cheap and fragile. Additionally, the use of specific materials and finishes can enhance the functional aspects of a product, such as improving grip ergonomics or facilitating ease of cleaning.

Our located in Hong Kong provide unique advantages in terms of access to the material supply chain. It facilitate sample selection, testing, and on-site problem-solving, which can help to streamline the design process and ensure that the final product meets the desired standards of quality and functionality.

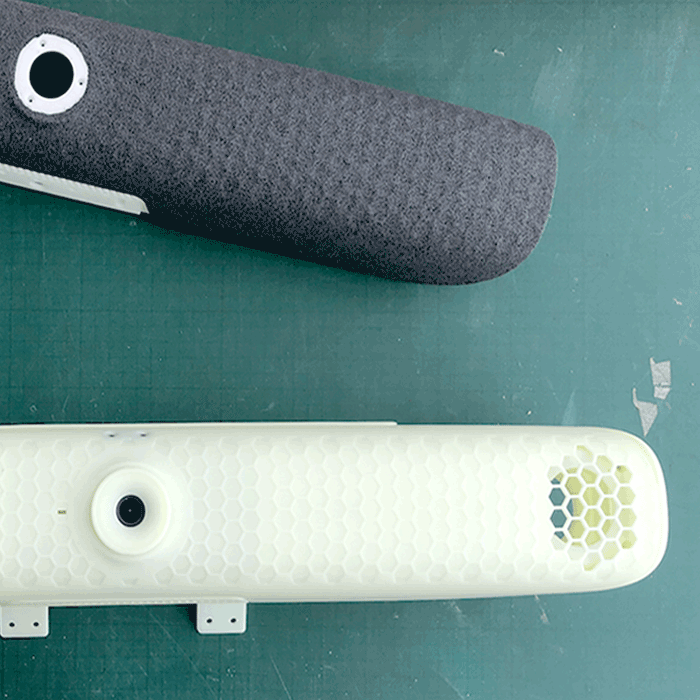

Prototypes

A prototype is a preliminary version or model of a product that is developed to test and validate an idea, concept, or process. The use of prototypes offers numerous benefits throughout the design process, as the fidelity of the prototype increases as the design progresses towards completion. Prototyping is a critical aspect of the design process, as it enables the verification of initial ideas, proportions, ergonomics, as well as the testing of CMF (color, material, finish) and feasibility in the design validation process (DVP).

- Early tests mock-ups – Paper or foam

- Refined mock-ups – 3D printed, CNC milling

- Cosmeting Prototypes – CMF verification

- Working Prototypes – Feasibility testing

- Small quantity production – Pilot testing

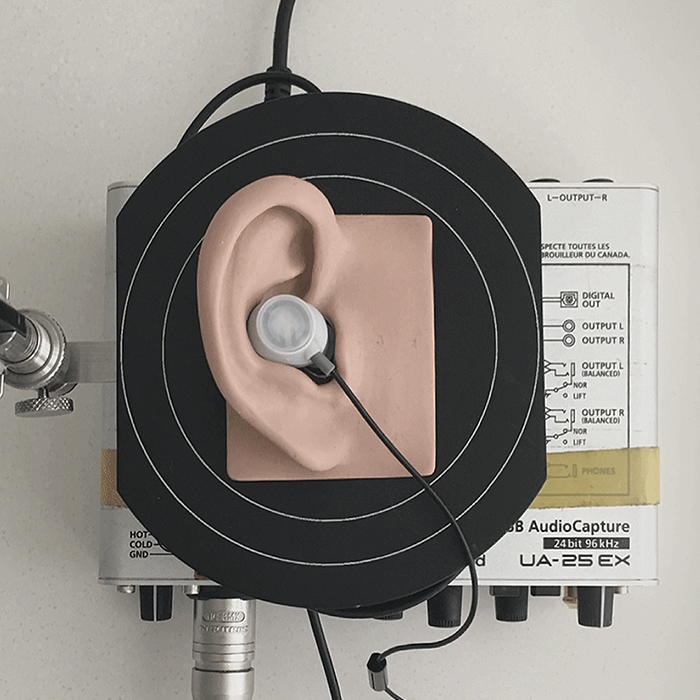

Human Factors

Human factors encompass the unique qualities of individuals that impact their experience of using a product or service. It is well known that when things fail to work as expected, it can lead to frustration and disappointment. Moreover, human behaviour at work can significantly affect health, safety, and usability. Therefore, it is essential to consider human factors when designing products or services.

Some of the key areas for design includes;

- Ergonomics interface

- Visualisation and heriachy of data

- Customisation

When developing new solutions for the IoT you have to incorporate User Experience testing into your device roadmap. Opting out of this testing can led to extemely expensive failusres.

Interface Design focuses on anticipating what users might need to do and ensuring that the interface has elements that are easy and intuitive to use, understand, and access. UI brings together concepts from interaction design, visual design, and information architecture.

- Graphic user interface

- Voice commands (siri)

- Interactive interface (swipe left, right)

DFM is the process of designing products for ease of manufacturing. Ideally, DFM needs to occur early in the design process, well before tooling has begun. Properly-executed DFMA needs to include all the stakeholders — engineers, designers, contract manufacturer, mould builder and material supplier.

- 3D (DFMA)

- 2D drawings (CTQ CTF)

- CMF / MUS

- Part Lists / BOM

- Cosmetic Criteria

- PVT, DVT, EVT Prototypes

- Testing

Visual Inspection is the process in the late stages of manufacturing. It involves examining a component or piece of equipment using one’s naked eye to look for flaws and imperfections.

Sometimes we use non-specialised inspection equipment like for example a light box with natural uncoloured light used in colour matching.

Quite often, there is no empirical formula for finding defective products or inspecting a piece of equipment.

- Colour matching

- Golden samples

- Visual Inspection

Related ID Cases

Top